Introduction

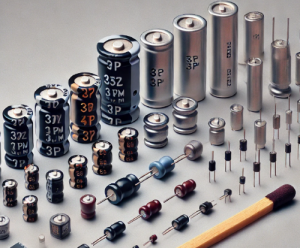

Capacitors are vital components in electronics, responsible for energy storage, filtering, and signal stabilization. Among the many capacitor types, tantalum capacitors and electrolytic capacitors are widely used due to their specific properties. In this article, we will compare tantalum capacitors with electrolytic capacitors, explaining their differences, benefits, and performance data to help you decide which is better for your needs.

1. What is a Tantalum Capacitor?

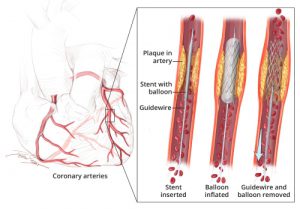

A tantalum capacitor is a type of electrolytic capacitor that uses tantalum metal as the anode, with tantalum pentoxide as the dielectric. Tantalum capacitors are known for their high capacitance per volume, which makes them compact while providing excellent performance. They offer high stability, low leakage current, and a long operational life. Tantalum capacitors are generally used in applications requiring long-term reliability, such as medical devices, military electronics, and aerospace systems.

2. What is an Electrolytic Capacitor?

An electrolytic capacitor typically uses aluminum as the anode with an oxide layer as the dielectric and a liquid or solid electrolyte as the cathode. Electrolytic capacitors are favored for their ability to offer high capacitance values at low cost. These capacitors are often used in applications that require bulk energy storage, such as power supplies and amplifiers.

Here is a comparison table of their key features:

| Feature | Tantalum Capacitor | Electrolytic Capacitor |

| Anode Material | Tantalum | Aluminum |

| Dielectric | Tantalum Pentoxide | Oxide layer

on Aluminum |

| Capacitance Range | 0.1 µF to 1000 µF | 1 µF to 100,000 µF |

| Voltage Ratings | 1.8V to 50V | 6V to 500V |

| Temperature Range | -55°C to +125°C | -40°C to +85°C

(up to 105°C in some models) |

| Equivalent Series

Resistance (ESR) |

Low ESR | Higher ESR |

| Size | Compact, high capacitance

per volume |

Larger, bulkier |

3. Tantalum Capacitor vs. Electrolytic Capacitor

–Construction and Materials

Tantalum capacitors use a solid tantalum core. The tantalum pentoxide dielectric is exceptionally thin, allowing for high capacitance in small sizes. Due to the stable dielectric material, tantalum capacitors are highly reliable.

Electrolytic capacitors typically use an aluminum core with a liquid or solid electrolyte, which restores the dielectric during operation. The construction leads to a larger physical size but supports higher capacitance and voltage ranges.

Further reading: What are the Differences Between Electrolytic, Tantalum, And Ceramic Capacitors?

–Performance Data and Capacitance Comparison

Tantalum capacitors offer capacitance values that can reach up to 1000 µF in compact designs, making them ideal for use in portable electronics and precision circuits. They have low equivalent series resistance (ESR), typically ranging from 0.1 to 1 ohm. This low ESR ensures minimal power loss, which makes tantalum capacitors highly effective in high-frequency filtering applications.

Electrolytic capacitors, particularly aluminum types, are known for their higher capacitance values, often exceeding 10,000 µF. For instance, aluminum electrolytic capacitors with capacitance values around 4700 µF are commonly used in power supply circuits. However, their ESR can range from 0.5 ohms to over 5 ohms, depending on the specific model. This higher ESR makes electrolytic capacitors less suitable for applications requiring efficient high-frequency filtering.

–Size and Form Factor

Tantalum capacitors are compact, with sizes as small as 0.6 mm x 0.3 mm in surface-mount packages. This makes them ideal for space-constrained applications such as smartphones and medical implants.

Electrolytic capacitors are typically larger due to their construction. For example, a 4700 µF aluminum electrolytic capacitor may be several centimeters in diameter, making them less suitable for small devices.

–Reliability and Lifespan

Tantalum capacitors are known for their high reliability, especially in low-voltage applications. They have lower leakage currents and longer operational lives, typically lasting over 10,000 hours in harsh environments.

The lifespan of electrolytic capacitors is shorter, particularly in high-temperature environments where the electrolyte can evaporate. A typical aluminum electrolytic capacitor may last around 2,000 to 5,000 hours at 85°C, although some models rated for 105°C can last longer.

–Voltage and Temperature Ratings

Tantalum capacitors are typically rated for lower voltages, up to 50V. However, they can withstand higher temperatures (up to 125°C) and maintain their stability over a wide range of temperatures.

Electrolytic capacitors can handle much higher voltages, with ratings up to 500V or more, which makes them suitable for power circuits. However, their performance may degrade in extreme temperatures.

— Cost Considerations

Tantalum is a rare metal, and its capacitors tend to be more expensive. A typical surface-mount tantalum capacitor (10 µF, 25V) may cost several times more than an equivalent electrolytic capacitor.

Aluminum electrolytic capacitors are significantly cheaper and more accessible. For example, a 4700 µF, 25V aluminum capacitor can cost less than a dollar, making them an affordable choice for high-volume applications.

–Use Cases

Tantalum capacitors are best suited for high-reliability applications where space is limited, such as in medical implants, smartphones, and aerospace systems. Their low equivalent series resistance (ESR) and long operational life make them particularly well-suited for use in high-frequency circuits that require stable and consistent performance.

Electrolytic capacitors are commonly used in applications that require high capacitance and higher voltage ratings, such as in power supplies, audio amplifiers, and motor drives. These capacitors are ideal for circuits that prioritize energy storage and bulk capacitance over compactness and precision.

Conclusion

In summary, tantalum capacitors excel in compactness, stability, and long-term reliability, making them the preferred choice for high-precision and space-constrained applications. Electrolytic capacitors, on the other hand, offer higher capacitance values and are more cost-effective for high-voltage and power-intensive applications. Your choice between the two should be based on the specific needs of your circuit, including size, voltage, capacitance, and cost. For more metals and alloys, please visit Advanced Refractory Metals (ARM).

[1]

[1]

[1]

[1] [2]

[2]

Recent Comments