The choice of a man’s wedding ring is a very important task when it comes to marriage. Tantalum rings herald a combination of timelessness, lifestyle and individuality. Whether you are looking for a classic or unique wedding band, choosing the right metal is an integral part of the experience.

Men’s wedding bands on the market are made of gold, sterling silver, platinum, titanium and tungsten. However, another type of wedding band is on the rise: the tantalum ring.

If you are looking for a men’s engagement ring that is popular for its luster, durability and uniqueness, you may want to consider purchasing a wedding band made of tantalum.

Tantalum has recently emerged in the wedding ring industry, but tantalum is a hard, lustrous metal that has been used extensively in the industry since the 19th century. So, what is tantalum? Is it a reliable metal? Is this expensive? Is it better than titanium?

We’ll address all your questions in this complete guide to tantalum rings.

What is tantalum?

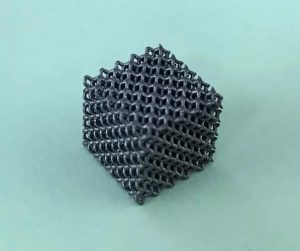

In its natural form, tantalum is a dense mineral that can be highly molded by heat or electricity, making it a great choice for industrial use. Tantalum has a deep, vivid color, darker than platinum. Because of its strength and utility, tantalum is a popular metal used in jewelry, including tantalum rings, bands and watches.

Tantalum has been around for centuries, but it has a vintage vibe that makes it unique in the jewelry market. For example, the name tantalum comes from the Greek mythological figure Tantalus. However, don’t let its ancient origins fool you. Tantalum is currently used in the field of energy, including capacitors and resistors.

The appeal of tantalum wedding rings is that they combine classic elegance with a modern, futuristic appeal. Tantalum rings are lightweight, masculine, strong, and unique. They are particularly resistant to corrosion because they are made of durable industrial materials.

Tantalum wedding rings are a unique variant that combines fluidity, aesthetics and industrial toughness.

Tantalum ring advantages

Tantalum’s durability: We keep trying again and again, and rings made of tantalum are durable.

Unlike tungsten, another popular men’s wedding ring, tantalum is shatterproof. A trustworthy and durable choice, tantalum is tough enough for those who work with their hands.

Appearance: Thanks to the metal’s natural luster, tantalum has a beautiful shine. Depending on your style, Tantalum rings are available in matte or polished finishes.

Tantalum is a pro-biological material, it is harmless and is often used in medical procedures and is safe for people with sensitive skin or those prone to allergic reactions.

Resizing: Can I resize my Tantalum ring? Yes. If your ring size changes, Tantalum will provide you with the option to easily resize your ring instead of replacing it. In contrast, both titanium and tungsten are difficult to resize.

Tantalum is easy to clean: Tantalum is very easy to maintain and does not require special cleaning by a professional jeweler. Simply wash with detergent-free soapy water to add a sparkling clean shine to rings and bands made of tantalum.

Are there any disadvantages to Tantalum wedding rings?

While tantalum wedding bands are a popular choice, there are still some drawbacks to consider.

For example, tantalum itself is a conflict metal. What does this mean? Well, according to the U.S. Geological Survey, about 10 percent of tantalum comes from a conflict mineral region in the Congo, where smuggling and exporting has created a serious crisis.

Tantalum contamination from dissolved particles to the earth’s fresh water and soil has also raised environmental concerns. But, as with other metals, including titanium and tungsten, the data is vague and contradictory.

Another drawback of tantalum rings is the lack of design versatility. Unlike the three metals (gold, silver and platinum), tantalum wedding bands are relatively new to men’s rings. This means that there are limited designs of tantalum wedding bands and wedding bands for men, and almost non-existent options for women.

Are these drawbacks enough to deter potential buyers from purchasing a tantalum wedding band? It depends on the buyer’s priorities, but there is no denying that the pros of tantalum rings may outweigh the cons.

Tantalum Rings

Tantalum is highly malleable, meaning it can withstand wear and tear without cracking or breaking. In fact, tantalum is practically shatterproof.

How much does a tantalum ring cost?

Tantalum rings are slightly more expensive than titanium or tungsten rings, and for good reason. Tantalum is a rare metal that makes up only 1-2 PPM (parts per million) of the earth’s crust.

Tantalum is a rare material and is therefore valued. In addition, tantalum rings are made with high-quality craftsmanship, which adds to the price and novelty of tantalum wedding bands.

Should I buy a tantalum ring?

At this point, this is a complete breakdown of tantalum rings and we hope we have answered all your questions in this guide. However, there is still the question, “Should I buy a tantalum ring?”

Ultimately, choosing a men’s wedding ring is a highly personal and subjective process. Only you can decide which ring is right for you.

Conclusion

Tantalum wedding bands are particularly attractive because tantalum is a rare metal. Tantalum rings are long-lasting, which means you don’t have to worry about delicate or fragile wedding bands. Tantalum wedding bands are timeless, durable, and unique.

Recent Comments