Niobium vs. Tantalum

Due to their similar properties as functional and structural materials, niobium and tantalum have common areas of application or in most cases can be substituted for each other. In practice, however, the main areas of application and usage vary considerably due to differences in resources and properties. Niobium is abundant and is produced and consumed in large quantities; tantalum is less abundant and is produced and consumed in small quantities.

Chemical properties of tantalum

Tantalum has excellent chemical properties and is extremely resistant to corrosion, not reacting to hydrochloric acid, concentrated nitric acid, or “aqua regia”, both under cold and hot conditions. However, tantalum can be corroded in hot concentrated sulfuric acid. Below 150°C, tantalum will not be corroded by concentrated sulfuric acid, but will only react above this temperature.

In 175 degrees in concentrated sulfuric acid for 1 year, the thickness of the corrosion is 0.0004 mm, tantalum into 200 degrees in the sulfuric acid soaked for a year, the surface layer is only damaged 0.006 mm. At 250 degrees Celsius, the corrosion rate increases to 0.116 mm per year.

At 300 degrees, the rate of corrosion is accelerated, soaking 1 year, the surface was corroded 1.368 mm. In fuming sulfuric acid, the corrosion rate is more severe than in concentrated sulfuric acid, and the surface is corroded to a thickness of 15.6 mm after 1 year of immersion in the solution at 130 degrees.

Tantalum uses and applications

-

Electronic industry:

The dense oxide film formed on the surface of tantalum metal has the one-way conductivity of valve metal, which is suitable for making capacitors with high reliability and long life and is widely used in military equipment and high-tech fields such as missiles, radar, TV, electronic computers, cell phones, etc. In 2000, 24 billion tantalum capacitors were produced worldwide.

-

Steel industry:

85% ~ 90% of the world’s niobium is used in steel production in the form of Ferro niobium. It is the leading micro-alloying element for niobium steel. When 0.1% of the alloying element is added, the yield strength of steel (N/mm2) increases as follows: niobium 118, vanadium 71.5, molybdenum 40, manganese 17.5, titanium 0. In fact, only 0.03% ~ 0.05% of Nb increases the yield strength of steel by more than 30%. As an alloying element, niobium is mainly used in the production of stainless steel and high strength low alloy steel (HSLA), which is widely used in oil transportation, gas pipelines, the automotive industry, shipbuilding, railroad transportation, construction industry, heavy machinery, and port construction.

-

Atomic energy industry:

Niobium has the advantages of high melting point, corrosion resistance, and relatively small thermal neutron capture cross-section, suitable for the manufacture of reactor uranium heating elements of the cladding tube and superheater.

-

Petroleum and chemical industries:

Niobium and tantalum have high corrosion resistance, good strength and processing plasticity and are excellent structural materials for chemical equipment. Used in the production of inorganic acids (nitric acid, sulfuric acid, hydrochloric acid), petroleum refining, and other equipment.

-

aerospace air industry:

Niobium-tantalum thermal strength alloy has good thermal strength, heat resistance and processing properties, widely used in the manufacture of aerospace air engine parts and gas turbine blades. In the United States, almost all the thermal parts of jet fighter engines are made of niobium alloys.

-

Cemented carbide:

Tantalum carbide is an important additive to cemented carbide, and its hardness is second only to diamond. Tantalum carbide is widely used in machining, the automotive industry, petroleum, and geological drilling tools, etc.

-

Superconducting materials:

Some niobium alloys and compounds have high superconducting transition temperatures and are used in the manufacture of various industrial superconductors, such as superconducting generators, gas pedal high-power magnets, superconducting magnetic energy storage devices, nuclear magnetic resonance imaging equipment, etc.

-

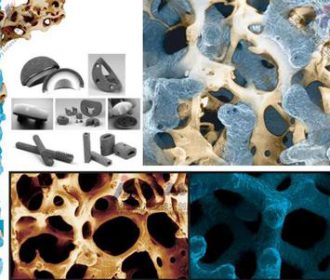

Medical field:

Tantalum and niobium have good biocompatibility and physiological corrosion resistance. Medical tantalum and niobium are used in the manufacture of bone plates, cranial plate screws, implant roots, surgical instruments, etc.

Recent Comments