Introduction:

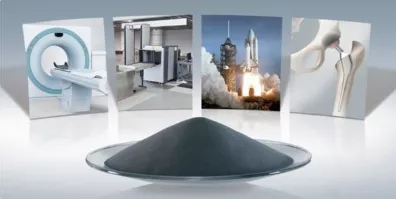

In the pursuit of sustainable energy solutions, researchers and engineers are constantly exploring innovative materials that can revolutionize energy storage systems. One such material that has emerged as a hidden gem in the field is tantalum oxide powder. While tantalum oxide has long been recognized for its exceptional electrical properties, its potential in energy storage has recently come to the forefront. This article delves into the fascinating role of tantalum oxide powder in energy storage and highlights its promising applications.

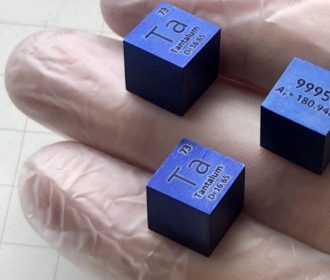

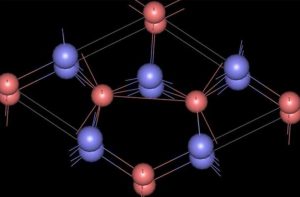

Understanding Tantalum Oxide Powder:

Tantalum oxide powder is a compound composed of tantalum and oxygen atoms. It possesses unique properties that make it a compelling candidate for energy storage applications. The powder form provides a high surface area, enabling greater contact with electrolytes and enhancing electrochemical reactions. Additionally, tantalum oxide exhibits excellent dielectric properties and stability, making it highly suitable for capacitive energy storage systems.

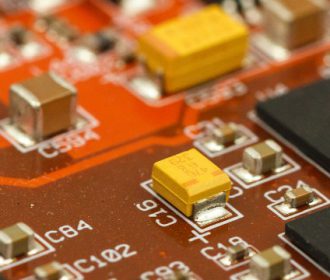

Advancing Capacitors: Tantalum Oxide Powder’s Capacitive Potential:

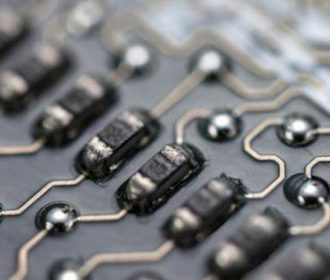

Capacitors play a crucial role in energy storage, especially in applications requiring rapid charge and discharge cycles. Tantalum oxide powder’s capacitive properties make it an ideal material for supercapacitors, which can store and deliver energy efficiently. The high surface area of tantalum oxide powder enables the formation of a robust electric double-layer, allowing for the rapid movement of charge carriers and enhancing energy storage capabilities.

Tantalum Oxide as a Catalyst in Energy Storage Systems:

Tantalum oxide powder also demonstrates remarkable potential as a catalyst in energy storage systems. It can facilitate critical electrochemical reactions, such as oxygen evolution and reduction reactions, which are essential for the efficient functioning of energy storage devices like fuel cells and batteries. By acting as a catalyst, tantalum oxide powder enhances the overall energy conversion efficiency and contributes to the longevity of the energy storage system.

Tantalum Oxide in Next-Generation Batteries:

As researchers strive to develop high-performance batteries with improved energy density, tantalum oxide powder has emerged as a promising component. By incorporating tantalum oxide nanoparticles into battery electrode materials, scientists have achieved enhanced energy storage capacity and improved cycling stability. Tantalum oxide’s ability to accommodate high charge and discharge rates makes it a valuable ingredient in the quest for next-generation battery technologies.

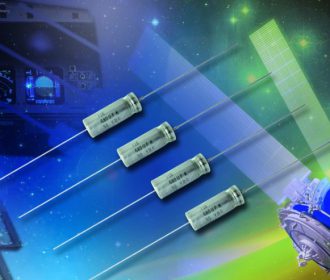

Tantalum Oxide Powder’s Role in Renewable Energy Integration:

The integration of renewable energy sources, such as solar and wind, into the power grid necessitates efficient energy storage solutions. Tantalum oxide powder’s excellent stability, high energy density, and fast response time position it as an ideal material for energy storage in renewable energy systems. Whether it’s storing excess energy generated during peak production or providing backup power during periods of low generation, tantalum oxide powder can help stabilize and optimize renewable energy integration.

Conclusion:

Tantalum oxide powder, once an overlooked material, has now emerged as a hidden gem in the realm of energy storage. Its unique properties, including high surface area, capacitive potential, catalytic activity, and compatibility with next-generation batteries, make it a versatile and valuable component in the quest for sustainable energy solutions. As researchers continue to explore and unlock its full potential, tantalum oxide powder is poised to play a pivotal role in shaping the future of energy storage, paving the way for a greener and more efficient world.

Recent Comments