Introduction

In the world of advanced materials and surface coatings, spherical tantalum carbide (TaC) powder has emerged as a game-changer. Its unique properties make it a preferred choice for thermal spraying applications across various industries. In this article, we will explore its versatile and innovative use in thermal spraying.

Advantages of Spherical TaC Powder

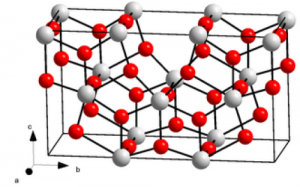

Spherical tantalum carbide (TaC) powder offers a range of remarkable advantages, including exceptional hardness, superior wear resistance, high melting point, chemical inertness, and excellent thermal conductivity

- Exceptional Hardness: It is renowned for its extreme hardness, ranking second only to diamond. When applied as a thermal spray coating, spherical TaC particles create a tough, wear-resistant surface that can withstand harsh environments and abrasive wear.

- High Melting Point: It boasts an incredibly high melting point, approximately 3,920 degrees Celsius (7,088 degrees Fahrenheit). This property makes it an ideal choice for applications requiring resistance to extreme temperatures and thermal stresses.

- Excellent Chemical Inertness: Spherical TaC particles are highly chemically inert, making them resistant to corrosion and chemical reactions. This attribute ensures the durability and longevity of thermal spray coatings in chemically aggressive environments.

- Enhanced Thermal Conductivity: TaC-based coatings exhibit excellent thermal conductivity. This property is valuable in applications where efficient heat dissipation is essential, such as in high-temperature industrial processes and aerospace components.

Applications of Spherical TaC Powder in Thermal Spraying

With these impressive features, TaC is applied to make components in aerospace, automotive, energy generation, chemical processing, and the oil and gas sectors.

- Aerospace Industry: In aerospace applications, thermal spray coatings of spherical TaC powder are used to protect critical components from extreme temperatures, wear, and oxidation. These coatings enhance the durability and longevity of turbine blades, combustion chambers, and other high-temperature parts.

- Automotive Sector: The automotive industry benefits from TaC-based thermal spray coatings for engine components, exhaust systems, and brake components. These coatings improve resistance to heat and friction, ultimately leading to enhanced engine performance and durability.

- Energy Generation: In power generation plants, spherical TaC coatings play a pivotal role in protecting boiler tubes, gas turbine components, and heat exchangers. They help maintain operational efficiency and prevent downtime due to wear and corrosion.

- Chemical Processing: The chemical industry utilizes TaC-based coatings to protect equipment exposed to corrosive chemicals and high temperatures. These coatings extend the service life of reactors, valves, and pipelines.

- Oil and Gas: In the oil and gas sector, TaC coatings are applied to drilling and production equipment to resist abrasive wear and corrosion in harsh environments. This improves the longevity of critical components and reduces maintenance costs.

Conclusion

Spherical tantalum carbide powder has revolutionized thermal spraying applications across industries by offering outstanding hardness, high-temperature resistance, chemical inertness, and thermal conductivity. Whether in aerospace, automotive, energy generation, chemical processing, or oil and gas, TaC-based coatings provide a reliable solution to protect critical components, extend service life, and enhance overall performance. For more information, you can check our website.

Recent Comments