If you need a metal foil that can withstand high temperatures and has extremely strong chemical resistance to most corrosive environments then tantalum foil is already on your short list of materials.

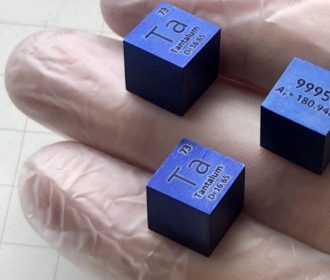

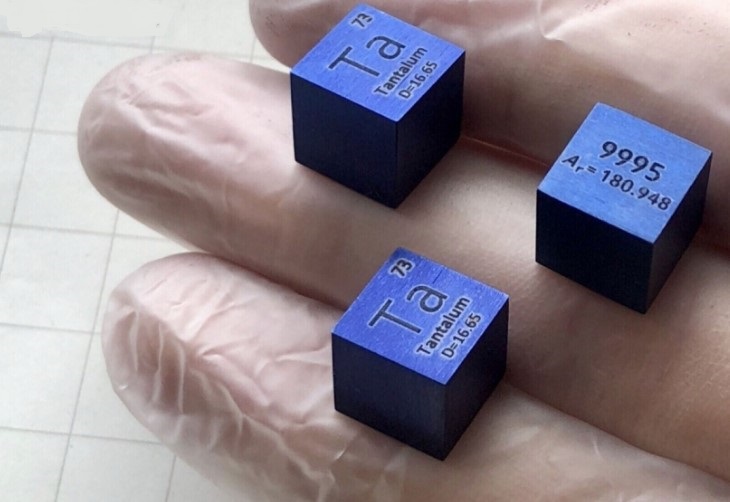

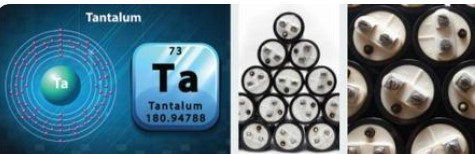

Tantalum belongs to a class of metals known as refractory metals, which are defined by their strong resistance to heat and wear. It has a melting point of 5,463 °F (2,996 °C), the fourth highest of all metals.

Like most metals, tantalum forms a thin but dense protective oxide layer (Ta2O5) when exposed to the atmosphere. This oxide layer firmly adheres to the surface of the metal, acting as a barrier that protects the underlying metal from further corrosion.

Below are some examples of common applications for tantalum foils.

Included with each application are some suggestions based on how others in that industry specify the tantalum foils for such uses. If your application is not on the list, we suggest contacting Stanford Advanced Materials’ technical sales at sales@samaterials.com.

Tantalum foils for Machined fasteners

Tantalum fasteners are made of alternative materials prone to failure or that require expensive equipment shutdowns for maintenance. Tantalum foils appear in industries such as mining, energy, and pharmaceuticals as well as in metal and chemical processing. For customers who prefer to make their own fasteners unannealed tantalum rod is most commonly requested. Annealed tantalum foils are sometimes difficult to machine because the metal has a tendency to gum. Unannealed tantalum foils make machining and threading easier. As a service to our customers, Stanford Advanced Materials also offers machined fasteners to your custom sizes.

Tantalum foils for Vacuum furnace heating elements

Because of tantalum’s oxidation resistance and high melting point, many vacuum furnace components incorporate tantalum foils. Grain-stabilized tantalum rod is designed to survive longer in high-temperature environments by reducing grain growth. Stanford Advanced Materials can grain stabilize tantalum foils by producing the product using a powder metallurgy process which creates a very uniform and fine grain size or as an alternative the rods can be produced with very small amounts of additives such a Yttrium. Either method prolongs or prevents the tantalum grains from growing and therefore increases machine life expectancy due to its ability to withstand high temperatures for long periods of time.

Tantalum foils for Machined parts for chemical processing equipment

Tantalum foils have corrosion-resistant properties which make it a choice material for machined parts used in chemical processing equipment. Tantalum machined parts replace inferior materials that do not perform as well in harsh chemical environments and require extensive maintenance. In most cases customer request tantalum 2.5% tungsten foil which has slightly more strength and corrosion resistance. When ordering tantalum rods for such applications we suggest you order ASTM B365 R05200 for pure tantalum rods or ASTM B365 R05252 for tantalum 2.5% tungsten foils.

Tantalum foils for X-ray/radiation shielding

Due to its high density, tantalum’s radio-opaque qualities make it ideal for X-ray and shielding applications seeking to prevent radiation leakage. Tantalum foils are often manufactured into shielding which protects sensitive electronic components in aerospace structures as well as components operating in corrosive environments. There is great variability in the tantalum foils used in applications such as this. Because the shielding is due to tantalum’s density, which is intrinsic, just about any grade of tantalum foil will be functional.

Tantalum foils for Sputtering Targets for Gun Barrels

Tantalum foils are sometimes used as a sputtering target to coat the inside of gun barrels with tantalum as a replacement for chromium. This makes the gun barrel manufacturing process more environmentally friendly and lets manufacturers reduce their ecological impact. When purchasing tantalum for such an application most customers prefer tantalum foils that are fully annealed, melted in an electron beam furnace (ASTM B365 R05200), and have a 99.95% minimum purity. Some customers have specified tantalum 2.5% tungsten or tantalum 10% tungsten foils.

Recent Comments