Introduction

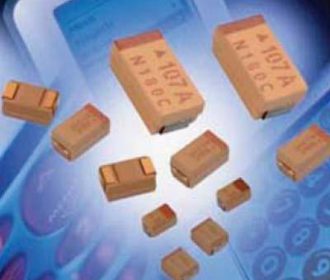

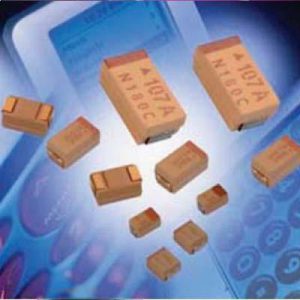

Tantalum capacitors play a crucial role in modern electronics due to their unique properties, such as high capacitance in small sizes, stability, and long lifespan. These advantages make them particularly valuable in applications where reliability, compactness, and efficiency are critical. Below are some of the key ways in which tantalum capacitors are used in modern electronic devices:

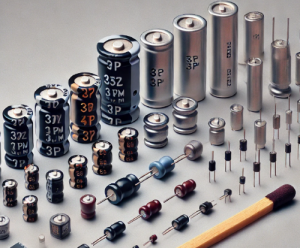

Key Features of Tantalum Capacitors

Known for their high capacitance and reliability, they are widely used in electronics where small size, stable performance, and long lifespan are essential.

- High Capacitance: They are capable of storing a large amount of energy in a compact form. Their high capacitance-to-size ratio makes them ideal for space-constrained applications.

- Stable and Reliable: They offer excellent stability and are less prone to failure compared to other types of capacitors, particularly in high-reliability environments.

- Small Size: With their compact size, Ta capacitors are used in small electronic devices without compromising performance.

- Long Lifespan: These capacitors are known for their long service life, particularly in harsh conditions, due to the corrosion-resistant nature of tantalum.

- Solid-State Construction: They have no liquid electrolyte. This design minimizes the risk of leakage or evaporation, improving their reliability in critical applications.

- Low ESR (Equivalent Series Resistance): The ESR makes them ideal for high-frequency applications and ensuring efficient power supply filtering.

- High Voltage Tolerance: They can operate effectively at higher voltages compared to other types of capacitors, which is crucial for many electronic devices.

Further reading: 3 Common Tantalum Products and Their Applications

1. Consumer Electronics

Tantalum capacitors are widely used in consumer electronics such as smartphones, tablets, laptops, and wearables. In these devices, the demand for compactness, lightweight components, and high efficiency is immense. Tantalum capacitors provide high capacitance in small packages, enabling efficient power management, noise filtering, and signal smoothing.

– Smartphones & Tablets: For power regulation, noise reduction, and maintaining stable voltage supply to critical components.

– Laptops: For smooth power supply and stable operation of high-speed processors and memory modules.

2. Power Supply Systems

Tantalum capacitors are integral to DC-DC converters, voltage regulation circuits, and power conditioning systems. Their ability to handle high voltage and provide stable capacitance makes them ideal for ensuring smooth and efficient power conversion in these systems.

– Power Supply Filtering: Tantalum capacitors are used to filter ripple and noise from power supply outputs, ensuring clean power for sensitive components.

– Voltage Regulation: They help stabilize voltage in power supplies to prevent fluctuations that could damage electronic components.

3. Automotive Electronics

Modern vehicles are increasingly relying on sophisticated electronic systems, from infotainment to safety features and electric vehicle (EV) systems. Tantalum capacitors are used in automotive applications due to their ability to perform well in harsh environments (e.g., high temperatures, vibrations) and their long lifespan.

– Infotainment Systems: Provide stable operation and noise filtering for high-definition displays, touchscreens, and audio systems.

– Electric Vehicles (EVs): Used in power management circuits, sensors, and battery management systems, ensuring the reliability and efficiency of EV electronics.

– Safety Features: Essential in systems like airbags, anti-lock braking systems (ABS), and collision detection, where reliability is critical.

4. Medical Devices

In medical electronics, such as pacemakers, defibrillators, and implantable devices, tantalum capacitors are valued for their long lifespan, reliability, and ability to perform in demanding environments. These capacitors ensure that critical devices remain functional over extended periods, which is essential for life-saving applications.

– Pacemakers & Defibrillators: Provide stable and efficient power regulation to the circuits controlling heart rhythms.

– Implantable Devices: Offer low ESR and high reliability for devices that must function reliably within the human body for many years.

5. Aerospace & Defense

Tantalum capacitors are a key component in aerospace and defense electronics due to their ability to withstand extreme temperatures, radiation, and mechanical stress. They are used in satellites, spacecraft, communication systems, and military electronics where reliability and performance in harsh conditions are paramount.

– Satellite Electronics: Power regulation and noise suppression in communication systems.

– Military Equipment: Used in radar systems, missile guidance systems, and communication devices, ensuring high reliability in critical applications.

6. Telecommunications

Telecommunications infrastructure, such as base stations, signal amplifiers, and fiber-optic systems, requires capacitors that can perform consistently under demanding conditions. Tantalum capacitors are used for power supply stabilization and filtering in these systems, where efficiency and reliability are crucial for maintaining continuous service.

– Base Stations & Signal Boosters: Ensure stable power supply and efficient noise filtering for uninterrupted communication.

– Fiber Optic Equipment: Used in the power management circuits of optical transceivers and amplifiers.

7. Wearables and IoT Devices

With the rise of wearable technology and the Internet of Things (IoT), smaller, low-power, and highly reliable electronic components are in demand. Tantalum capacitors help power these devices by stabilizing power and ensuring longevity, even in compact designs.

– Wearables: In fitness trackers, smartwatches, and medical monitors, where long battery life and consistent performance are crucial.

– IoT Devices: Used in sensors, connected home devices, and smart appliances to ensure stable operation and efficient energy use.

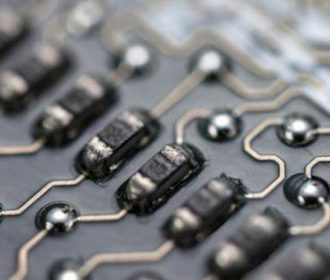

8. High-Frequency Circuits

Tantalum capacitors’ low ESR and high capacitance make them well-suited for high-frequency applications like radio-frequency (RF) circuits, microwave communications, and signal processing. They help filter out unwanted noise and stabilize voltage in these sensitive circuits.

– RF and Microwave Communication: Ensures stable performance in transmitters, receivers, and signal processors.

– Signal Processing Equipment: Helps maintain stable operation in precision electronic systems used for high-frequency applications.

Conclusion

Tantalum capacitors have become an indispensable component in modern electronics due to their unique characteristics, such as high capacitance, small size, low ESR, and excellent stability. They are used in a wide range of applications, from consumer electronics and automotive systems to medical devices, telecommunications, and aerospace. For more tantalum products, please check Advanced Refractory Metals (ARM).

Recent Comments