What is Tantalum?

–Tantalum the Element

Tantalum the element (Ta, 73) is located in Block D, Group 5, Period 6 in the periodic table, and its atomic weight is 180.94788. This metal element was first discovered by Anders G. Ekeberg in 1802, yet pure tantalum was extracted by Werner von Bolton in 1903. Then, pure tantalum has been mainly mined from columbite-tantalite.

–Tantalum the Metal

Tantalum the metal is a typical refractory metal that is known for its high melting point and corrosion resistance. It looks lustrous gray-blue and has a melting point of 2980℃, which just falls after tungsten and rhenium. The density of pure tantalum is 16.4 g/cm3 and its elastic modulus is 185.7 GPa. All these figures indicate the thermal resistance and high strength of pure tantalum.

–Tantalum Applications

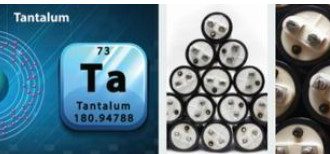

Because of these desirable mechanical and chemical properties, tantalum is applied to make lots of apparatus ranging from capacitors to reaction pipes.

First, nearly 50% to 70% pure tantalum contributes to the manufacturing of capacitors. A majority of capacitors are made from pure tantalum powers or wires. People choose this material because tantalum would form a passive oxide layer with dialectic strength. These capacitors could maintain ideal functions under high temperatures and high voltages. Additionally, tantalum capacitors are employed in the making of switches, mobile phones, fax machines, computers, automobiles, and even defense and military industries.

You can also find pure tantalum in the healthcare and medical field. Thanks to no immune response, the metal material is commonly used to make surgical implants. It can replace skull plates, connects torn nerves, or weaves abdominal muscle.

Pure tantalum could also be applied to make pipes for chemical reactions and heat exchangers for its unique corrosion and heat resistance ability. It can be generally found in the fields of aerospace and metallurgy.

What is Tantalum Tungsten Alloy?

–Tungsten the Element

Tungsten the element (W, 74) is a Block D, Group 6, Period 6 metal element with an atomic weight of 183.84. It was found by Torbern Bergman in 1781. Tungsten has the highest melting point (3420℃) of all the metallic elements, and its density is about 1.7 times that of lead. This element is also famous for its high strength and melting point.

–Types of Tantalum Tungsten Alloy

The tantalum tungsten alloys have 3 variants according to their percentage of tungsten added. Ta2.5W, or tantaloy60, has 2.5% tungsten and 0.5% niobium. Ta7.5W, or tantaloy61, has 7.5% tungsten, while Ta10W possesses 10% tungsten and is also called tantaloy63. These alloys have a high melting point of 3005-3030 °C and a large density of 16.7-16.9 g/cm3.

–Tantalum Tungsten Alloy Applications

The application fields of tantalum tungsten alloys lie in the chemical processing industry and heater exchange industry. Similar to pure tantalum, these tantalum tungsten alloys keep useful features such as high melting point, tension resistance, and high corrosion resistance. An oxide layer is formed on the surface and is stable at temperatures below 260°C. This layer could also stand strong hot acids like HCl and H2SO4. Because of great thermal conductivity, these alloys are also commonly found to make heat exchangers.

Comparison between Them

Pure tantalum and tantalum tungsten alloys have similarities and disparities in properties and application fields.

As for physical and chemical properties, pure tantalum metal and its alloys with tungsten content share some common points. Tantalum tungsten alloys are strong materials withstanding high temperatures just like pure tantalum. More importantly, they have higher melting points and density, representing their higher strength. Detailed information is listed as follows.

Table 1 Comparison between

Pure Tantalum and Tantalum Tungsten Alloy

| Ta | W | Ta2.5W | Ta7.5W | Ta10W | |

| Melting Point (°C) | 2980 | 3420 | 3005 | 3030 | 3025 |

| Density (g/cm3) | 16.4 | 19.24 | 16.7 | 16.8 | 16.8 |

| Elastic Modulus (GPa) | 185.7 | N/A | 195 | 205 | 200 |

In terms of uses and applications, you can find them both used as chemical reaction pipes and heat changers. However, pure tantalum finds its special applications as capacitors and surgical implants. You’d better take budgets and efficiency into consideration since the tantalum tungsten alloy is a bit more costly but efficient than the pure tantalum.

Recent Comments