Is tantalum a precious metal?

Tantalum, a metallic element, is found mainly in tantalite and is symbiotic with niobium. Tantalum is moderately hard, ductile, and can be drawn into thin foil in the form of filaments. Its coefficient of thermal expansion is very small. Tantalum has excellent chemical properties and is extremely resistant to corrosion.

Although tantalum is highly resistant to corrosion, its corrosion resistance is due to the generation of a stable protective film of tantalum pentoxide (Ta2O5) on the surface. It does not react to hydrochloric acid or concentrated nitric acid, either under cold or hot conditions. It can be used to make evaporating vessels, etc. It can also be used as electrodes for electronic tubes, rectifiers, and electrolytic capacitors. It is also used in medical treatment to make thin sheets or threads to mend damaged tissues.

Why is tantalum so rare?

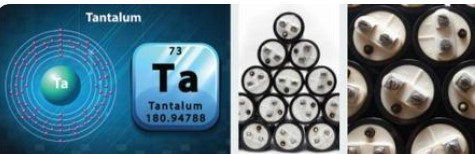

Chemical symbol Ta, gray metal, in the periodic table belongs to the VB group, atomic number 73, atomic weight 180.9479, body-centered cubic crystal, common chemical compound valence +5.

Tantalum was discovered by the Swedish chemist A.G. Ekeberg in 1802 and named tantalum after the Greek mythological figure Tantalus (Tantalus). 1903, the German chemist W. von Bolton prepared the first plastic metal tantalum for use as filament material. 1940, large-capacity tantalum capacitors appeared and were widely used in military communications.

In 1940, large-capacity tantalum capacitors appeared and were widely used in military communications. During the Second World War, the demand for tantalum increased dramatically, and after the 1950s, the demand for tantalum rose year by year due to its expanding applications in the capacitor, high-temperature alloy, chemical, and atomic energy industries, promoting the development of research and production of tantalum extraction processes.

What are the Features of Tantalum?

The hardness of tantalum is low and correlates with the oxygen content; ordinary pure tantalum, in its annealed state, has a Vickers hardness of only 140 HV. It has a melting point of 2995°C and ranks fifth among the monomers, after carbon, tungsten, rhenium, and osmium. Tantalum is ductile and can be drawn into thin foils of the filament type. Its coefficient of thermal expansion is very small. It expands by only 6.6 parts per million per degree Celsius. In addition, it is very ductile, more so than copper.

Tantalum Chemical properties.

Tantalum also has excellent chemical properties and is extremely resistant to corrosion, not reacting to hydrochloric acid, concentrated nitric acid or “aqua regia” under both cold and hot conditions. However, tantalum can be corroded in hot concentrated sulfuric acid. Below 150°C, tantalum will not be corroded by concentrated sulfuric acid, but will only react above this temperature. At 250 degrees, the rate of corrosion increased to 0.116 mm per year, and at 300 degrees, the rate of corrosion was accelerated, and the surface was corroded by 1.368 mm after 1 year of immersion.

In the fuming sulfuric acid (containing 15% SO3) corrosion rate is more serious than in concentrated sulfuric acid, soaked in the solution at 130 degrees for 1 year, the surface is corroded by a thickness of 15.6 mm.

Tantalum is also corroded by phosphoric acid at high temperatures, but the reaction generally occurs at 150 degrees or more, and the surface is corroded by 20 mm when immersed in 85% phosphoric acid at 250 degrees for 1 year. In addition, tantalum can be rapidly dissolved in a mixture of hydrofluoric acid and nitric acid, and can also be dissolved in hydrofluoric acid. But tantalum is more afraid of strong bases.

In a caustic soda solution with a concentration of 40% at 110 degrees, tantalum will be dissolved rapidly, and in a potassium hydroxide solution with the same concentration, it will be dissolved rapidly for as long as 100 degrees.

Except for the above-mentioned cases, general inorganic salts generally cannot corrode tantalum below 150 degrees. Experiments have shown that at room temperature, tantalum does not react to alkaline solutions, chlorine gas, bromine water, dilute sulfuric acid, and many other agents, but only to hydrofluoric acid and hot concentrated sulfuric acid. This is a relatively rare occurrence among metals.

What are tantalum used for?

Tantalum has properties that make it very versatile. In equipment for the production of various inorganic acids, tantalum can be used as a replacement for stainless steel, with a life expectancy several dozen times longer than that of stainless steel.

In addition, in the chemical, electronic and electrical industries, tantalum can replace the tasks that used to be undertaken by the precious metal platinum, making the costs required much lower. Tantalum is manufactured into capacitors equipped into military equipment.

The United States has an exceptionally developed military industry and is the world’s largest arms exporter. Half of the world’s tantalum production is used in the production of tantalum capacitors, and the U.S. Department of Defense Logistics Agency is the largest owner of tantalum, having at one time bought out one-third of the world’s tantalum powder.

Where is tantalum found in?

Tantalum is one of the rare metal mineral resources and is a strategic raw material indispensable for the development of the electronics industry and space technology.

Tantalum and niobium have similar physicochemical properties and are therefore co-occurring in minerals in nature. The classification of tantalum or niobium ore is mainly based on the content of tantalum and niobium in the mineral, which is called niobium ore when the niobium content is high and tantalum ore when the tantalum content is high.

Niobium is mainly used in the manufacture of carbon steel, super alloys, high-strength low-alloy steel, stainless steel, heat-resistant steel and alloy steel; tantalum is mainly used in the production of electronic primary devices and alloys.

Tantalum and niobium minerals are complex in form and chemical composition, which in addition to tantalum and niobium, often also contain rare earth metals, titanium, zirconium, tungsten, uranium, thorium, and tin.

The main minerals of tantalum are tantalite [(Fe, Mn)(Ta, Nb)2O6], heavy tantalite (FeTa2O6), fine crystal [(Na, Ca)Ta2O6(O, OH, F)], and black rare gold ore [(Y, Ca, Ce, U, Th)(Nb, Ta, Ti)2O6], etc. The waste residue of tin refining contains tantalum, which is also an important resource of tantalum.

Recent Comments