Introduction

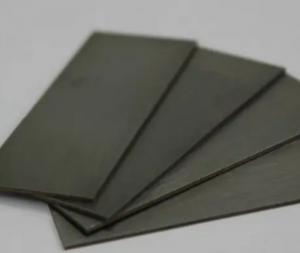

Tantalum, a transition metal known for its remarkable corrosion resistance and high melting point, is a valuable material in a wide range of industries. However, to cater to specific applications, tantalum is often alloyed with other elements, creating tantalum alloys. These alloys combine tantalum’s inherent properties with those of other metals to enhance characteristics like strength, heat resistance, and corrosion resistance. This article delves into the world of tantalum alloys, examining various types and their applications.

Tantalum-Tungsten (Ta-W) Alloys

Tantalum-W, or Ta-W alloys, are designed for applications that require high-temperature resistance. By combining tantalum with tungsten, these alloys offer superior heat resistance, making them suitable for industries such as aerospace and electronics, where components are exposed to extreme temperatures.

Related reading: What Is Tantalum Tungsten Alloy?

2. Tantalum-Niobium (Ta-Nb) Alloys

Tantalum-Niobium alloys are prized for their corrosion resistance. These alloys find their way into chemical processing and aerospace, among other applications. They are known for their enhanced strength and ductility, making them versatile choices in demanding environments.

3. Tantalum-Hafnium (Ta-Hf) Alloys

Tantalum-Hafnium alloys are ideal for nuclear applications due to their exceptional stability at high temperatures. These alloys are used in nuclear reactors, ensuring the safe containment of radioactive materials.

4. Tantalum-Titanium (Ta-Ti) Alloys

In the medical field, tantalum-titanium alloys are utilized for biocompatible implants. These alloys combine tantalum’s corrosion resistance with the lightweight properties of titanium, making them suitable for surgical implants and prosthetics.

5. Tantalum-Zirconium (Ta-Zr) Alloys

Ta-Zr alloys are corrosion-resistant materials often employed in chemical processing. Their ability to withstand hot acids and aggressive chemicals makes them crucial for industries that deal with corrosive substances.

6. Tantalum-Nickel (Ta-Ni) Alloys

Ta-Ni alloys are popular in electronic components, as they offer tailored electrical properties. They provide a balance between electrical conductivity and corrosion resistance, making them ideal for various electronic devices.

Conclusion

Tantalum alloys have proven to be invaluable in various industries, offering a diverse range of properties tailored to specific applications. From high-temperature resistance in tantalum-tungsten alloys to biocompatible implants in tantalum-titanium alloys, the versatility of tantalum alloys continues to drive innovation in numerous fields. As technology advances and industries evolve, tantalum alloys will likely play an increasingly pivotal role in enabling cutting-edge solutions and ensuring the longevity and reliability of critical components. For more information, please check our homepage.