Tungsten and tungsten wire bulbs have the highest melting points of all metals. In addition, do you know which metal elements have melting points?

This article will take a look at the top ten metals with the highest melting points.

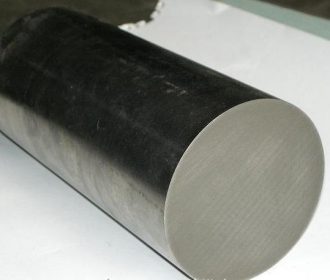

Tungsten

Tungsten is a silvery-white metal shaped like steel. It has the highest melting point of any metal element, up to 3422°C, and a boiling point of 5927°C, making it the highest melting point in the world. It is an ultra-high temperature-resistant metal, ranking first in the list of metals with the highest melting points. As a rare high melting point metal, tungsten is commonly used as a lamp filament because when an electric lamp is turned on, the filament reaches temperatures of up to 3000°C. Only tungsten can withstand such high temperatures. In addition, tungsten increases the high-temperature hardness of steel. Meanwhile, tungsten is widely used in the alloy, electronic and chemical industries because of its high melting point, high hardness, high density, and good electrical conductivity. At present, more than 20 kinds of tungsten minerals and tungsten-bearing minerals have been found on the earth.

Rhenium

Rhenium is a silvery-white rare metal with a high melting point. It has the second highest melting point of all metals, second only to tungsten. Its melting point is as high as 3180℃ and its boiling point is 5900℃. Because of its high melting point, rhenium is more difficult to obtain than diamonds and is one of the rarest elements in the earth’s crust, making it very expensive and among the most expensive metals in the world. Rhenium and its alloys are widely used in the aerospace, electronics industry, petrochemicals, and other fields, especially in high-efficiency jet engines and rocket engines, and are therefore of great importance in military strategy.

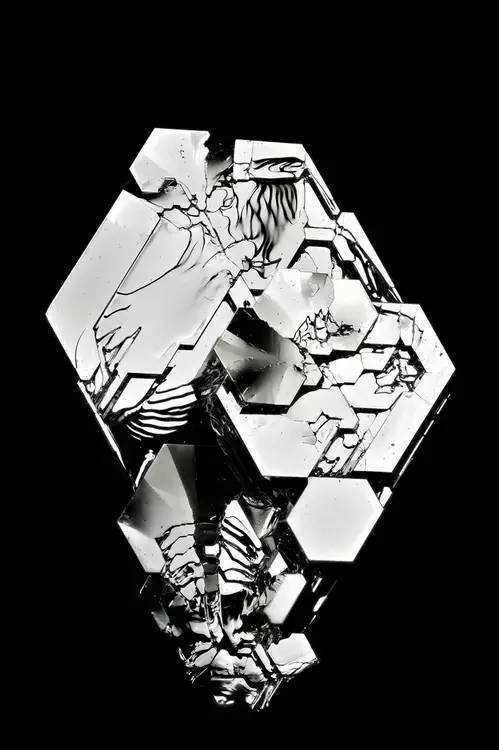

Osmium

Osmium is a high-density rare metal, belonging to the heavy platinum group of metals, and is the world’s highest density metal. Osmium is found in osmium-iridium ores, which are extremely difficult to mine because of their density of 22.48 g/cm3, a high melting point of 3045°C, and a boiling point above 5027°C, making them one of the three metals with the highest melting points in the world. Osmium has a wide range of applications and can be used to make ultra-hard alloys. It is mainly used as a catalyst in the industry. It is often used to make products with other metals to extend their life.

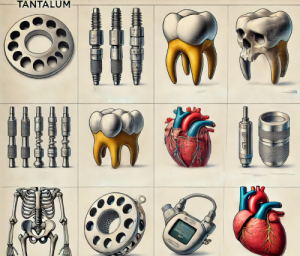

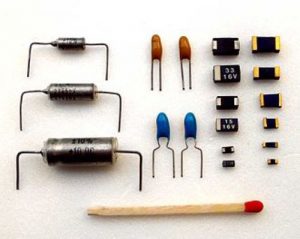

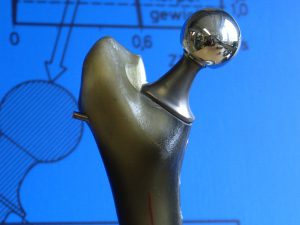

Tantalum

Tantalum is a rare metal mineral resource found mainly in tantalite, which coexists with niobium. With a density of 16.68 g/cm³, a melting point of 2980°C, and a boiling point of 5425°C, it is the fourth most insoluble metal after tungsten, rhenium, and osmium. As a rare metal, tantalum has a high melting point, low vapor pressure, good cold processing performance, high chemical stability, and strong resistance to liquid metal corrosion, and has a wide range of application prospects. It has important applications in high-tech fields such as electronics, metallurgy, steel, chemical industry, cemented carbide, atomic energy, superconductivity technology, automotive electronics, aerospace, and medical and scientific research. Almost half of the world’s tantalum metal production is used to produce tantalum capacitors.

Molybdenum

Molybdenum is a transition metal element. It is an essential trace element for humans, animals, and plants. It is also the metal element with the highest melting point. It has a density of 10.2 g/cm³, a melting point of 2610°C, and a boiling point of 5560°C. Molybdenum is a silvery-white metal that is hard and tough. Like tungsten, it is a refractory and rare metal. According to worldwide molybdenum consumption statistics, molybdenum still occupies the most important position in the steel industry, accounting for about 80 percent of total molybdenum consumption, followed by the chemical industry, which accounts for about 10 percent. In addition, molybdenum is also used in medicine, agriculture, and electrical and electronic technology, which accounts for about 10 percent of total consumption.

Niobium

What metal has the highest melting point? Niobium is one of the metals with the highest melting point in the world. Niobium is a silvery gray, soft, and ductile rare high melting point metal with a density of 8.57 g/cm³, a melting point of 2477°C, and a boiling point of 4744°C. At room temperature, niobium does not react with air, but at high temperatures, it combines directly with sulfur, nitrogen, and carbon. Niobium has good superconductivity, corrosion resistance, high melting point, and wear resistance and is widely used in steel, superconducting materials, aerospace, electronics industry, medical, and other fields. Niobium does not occur in nature in its pure state but is combined with other elements to form minerals. Brazil and Canada are still the largest producers of niobium concentrates.

Iridium

Iridium is extremely chemically stable in acids and is insoluble in acids. It is the most corrosion-resistant metal and the metal material with the highest melting point. Its density is 22.56 g/cm³, melting point 2450°C, and boiling point 4130°C. The amount of iridium in the earth’s crust is 1/10 million. It is often dispersed in various ores of alluvial deposits and alluvial mines together with platinum-based elements. It is rare precious metal material and belongs to the platinum family of metals. Iridium can be used in a wide range of industrial and medical applications due to its high melting point, high hardness, and corrosion resistance.

Ruthenium

Ruthenium is one of the platinum group metals. It is the least abundant of the platinum group elements in the earth’s crust and the last of the platinum group elements. Ruthenium is a rare transition metal with stable properties and high corrosion resistance, with a melting point of 2310°C and a boiling point of 3900°C, making it the highest melting point metal material in the world. It has a variety of uses and is commonly used in electronics. It is cheaper than rhodium, has very similar properties, and is commonly used to produce electrical contacts, wires, and electrodes.

Hafnium

Hafnium is a shiny silver-gray transition metal with a density of 13.31 g/cm³, a melting point of 2233°C, and a boiling point of 4603°C. It is one of the metals with the highest melting point on earth and ranks ninth among the metals with the highest melting point. in 1925, the Swedish chemist Hedwig and the Dutch physicist Kost obtained pure hafnium salts by stepwise crystallization of fluorine-containing complex salts and reduction with sodium metal to obtain pure Hafnium metal. Hafnium is rarely found in the earth’s crust and usually coexists with zirconium. Hafnium is used as an atomic energy material, alloy material, high-temperature resistant material, electronic material, etc. because of its high-temperature resistance, oxidation resistance, corrosion resistance, ease of processing, rapid heat absorption, and exotherm.

Technetium

What is a high melting point metal? Technetium is one of the metals with the highest melting point on earth, with a melting point of 2157℃ and a boiling point of 4265℃. Technetium is also the first element prepared by artificial methods. It was first obtained by bombarding molybdenum with deuterium (heavy hydrogen) in a cyclotron. The element symbol is TC. it belongs to group VIIB of the periodic table and the element is a silvery-white metal. Technetium is used as a tracer in metallurgy, low-temperature chemistry, corrosion-resistant products, nuclear fuel burn-up measurements, and medical research.

Rhodium

Rhodium is a silvery-white, hard metal that belongs to the platinum family of elements. It is also the most expensive precious metal in the world and is extremely rare. Rhodium has a higher melting point than platinum, with a melting point of 1966°C and a boiling point of 3727°C. Rhodium is insoluble in most acids, has a high melting point, and is surprisingly resistant to corrosion. This silver metal is commonly used because of its reflective properties. In addition to making alloys, it is also used as a bright and hard coating for other metals. However, due to the high price of rhodium, it is usually used only as an additive element, except for special applications.

Vanadium

Vanadium is a silvery-white metal and has one of the highest melting points of any metallic element. With a melting point of 1890°C and a boiling point of 3380°C, it has the element symbol v and belongs to the VB group in the periodic table of elements. It is known as a refractory metal along with niobium, tantalum, tungsten, and molybdenum. Among the properties of vanadium, it rarely forms as a stand-alone mineral and is mainly found in vanadium-titanium magnetite. However, world reserves of vanadium and titanium magnetite are enormous and are concentrated in a few countries and regions such as Russia, South Africa, Australia, and the United States. Vanadium is widely used in the metallurgical, aerospace, chemical, and battery industries in the form of ferrovanadium, vanadium compounds, and vanadium metal.

Recent Comments