What is tantalum?

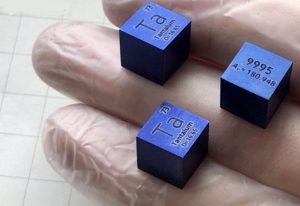

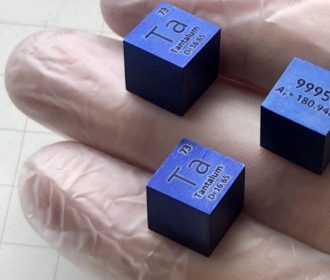

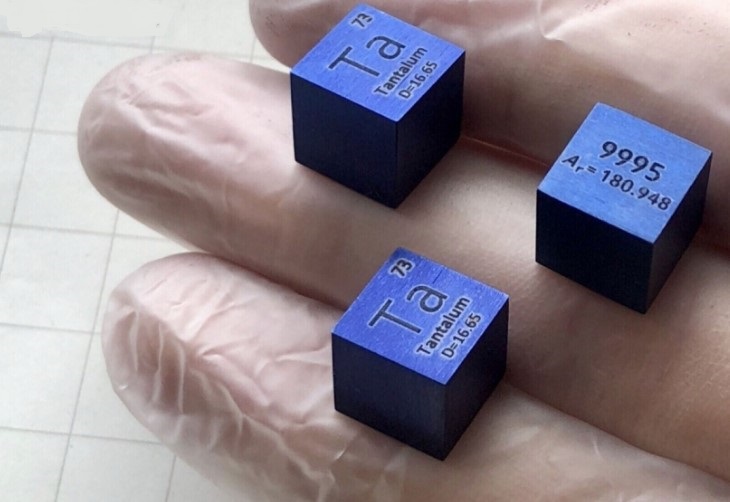

Tantalum is a metal element, element symbol is Ta, its atomic number is 73, its density is 16.68g/cm, and its melting point is 2980 DEG C, which is the third most refractory metal. Pure tantalum has a blue color, and excellent ductility, and can be rolled into a very thin plate in the cold state without intermediate annealing.

The corrosion resistance of tantalum is the same as that of glass. In the medium temperature (about 150 DEG C), only fluorine, hydrofluoric acid, sulfur trioxide, alkali, and some molten salts have an effect on tantalum. Tantalum is stable at room temperature, it will accelerate oxidation to produce Ta205 if heated to 500 DEG C.

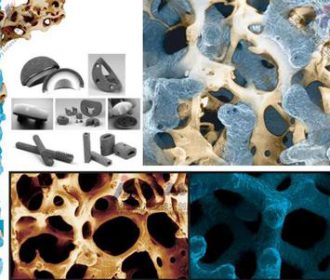

Tantalum has a series of excellent properties such as high melting point, low vapor pressure, and cold processing performance, high chemical stability, anti-corrosion ability, constant liquid metal oxide film, has important applications in electronics, metallurgy, the chemical industry, iron and steel, hard alloy, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research and other high-tech fields.

What is niobium?

What is Niobium?

Niobium is a rare high melting point metal. The melting point is 2467 degrees, the density is 8.6g/cm3, and the lattice type is body-centered cubic. The coefficient of linear expansion (0~100 C) is 7.1 x 10-6. Adding a small amount of niobium into a steel can greatly improve the strength of steel, improve the mechanical and welding properties of steel, and improve its corrosion resistance.

Niobium can be used as a capacitor and niobium-based superalloy. FS – 85 alloy is a structural material for the orbiting engine on the shuttle. C – 103 alloy can be used as a rocket nozzle material. Other niobium alloys, such as Nb – Zr, Nb – Ti, Nb – Ti – Ta, can be used as superconducting materials, and are widely used in magnetic resonance medical human images.

Niobium-based compounds and complexes can be used as catalysts to remove pollution, selective oxidation, and hydrogenation.

Is tantalum the same as niobium?

No. Tantalum and niobium are transition metals that are commonly found together in nature. They have very similar physical and chemical properties. Their properties of hardness, conductivity, and resistance to corrosion largely determine their primary uses today.

The reason for the similarity between niobium and tantalum is the size which is the result of the lanthanide contraction. Thus, the niobium and tantalum have the same size and due to the same size, tantalum and niobium have the same ionic and covalent radii.

Conclusion

Tantalum is chemically much like niobium because both have similar electronic configurations and because the radius of the tantalum ion is nearly the same as that of niobium as a result of the lanthanoid contraction. Niobium is a lustrous, gray, ductile metal with a high melting point, relatively low density, and superconductor properties. Tantalum is a dark blue-gray, dense, ductile, very hard, and easily fabricated metal. It is highly conductive to heat and electricity and renowned for its resistance to acidic corrosion.

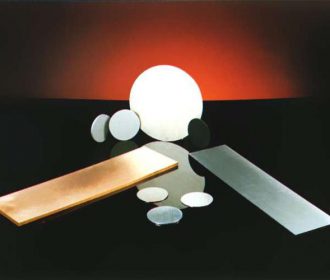

Stanford Advanced Materials produce our tantalum products from the metal powder to the finished product. We only use the purest tantalum powder as the source material. This is how we can guarantee you a very high material purity.

We guarantee a purity of 99.95% for our sintered quality tantalum (metallic purity without Nb). The remaining portion is made up primarily of the following elements according to a chemical analysis:

| Element | Typical max. value [μg/g] |

Guaranteed max. value [μg/g] |

| Fe | 17 | 50 |

| Mo | 10 | 50 |

| Nb | 10 | 100 |

| Ni | 5 | 50 |

| Si | 10 | 50 |

| Ti | 1 | 10 |

| W | 20 | 50 |

| C | 11 | 50 |

| H | 2 | 15 |

| N | 5 | 50 |

| O | 81 | 150 |

| Cd | 5 | 10 |

| Hg | – | 1 |

| Pb | 5 | 10 |

Recent Comments