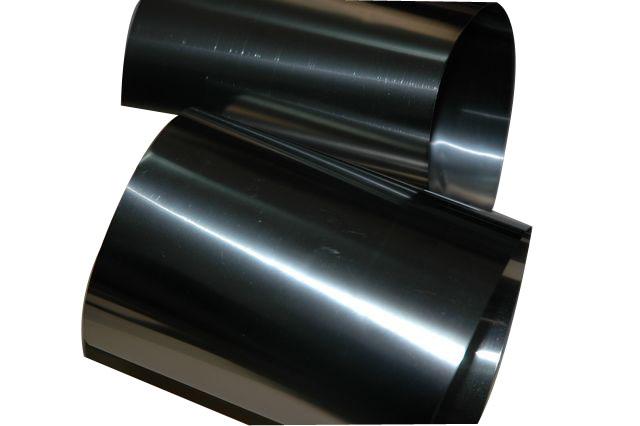

Tantalum is a kind of refractory nonferrous metal with a hardness of 6-6.5. Its melting point can reach 2996 ℃, which is second only to tungsten and rhenium. Tantalum is malleable and can be drawn into thin foil, and it has a very small coefficient of thermal expansion, which is only 0.6 percent for every degree rise.

Tantalum also has excellent chemical properties and is highly resistant to corrosion. Tantalum does not react with hydrochloric acid, concentrated nitric acid, and aqua regia under both cold and hot conditions. The experiments showed that tantalum did not react with the alkali solution, chlorine gas, bromine water, dilute sulfuric acid, and many other agents at room temperature, but only with hydrofluoric acid and hot concentrated sulfuric acid, which is relatively rare in metals.

Tantalum has a wide range of applications due to its excellent performance. For example, tantalum can be used as a substitute for stainless steel in the production of various inorganic acids. Besides that, tantalum can replace tasks that used to be undertaken by precious metal platinum in chemical, electronic, electrical, and other industries, thus greatly reducing the cost. Tantalum is manufactured into capacitor equipment for military use, and half of the world’s production of tantalum is used in tantalum capacitors. America’s military industry is unusually advanced, and it is the world’s largest arms exporter. The Defense Logistics Agency, the largest owner of tantalum, once bought a third of the world’s tantalum powder.

Tantalum is a kind of stable anodic oxide film in the acidic electrolyte. The electrolytic capacitor made of tantalum has the advantages of large capacity, small volume, and good reliability. Capacitor making is the most important use of tantalum, and the consumption of tantalum accounts for more than 2/3 at the end of the 1970s. Tantalum is also used to make electronic transmitter tubes and high-power tube parts. Moreover, Tantalum metal can be used as the structure of the combustor of the aircraft engine.

Tantalum and its alloys are widely used in all walks of life. Tantalum and tantalum-hafnium alloys are often used as heat-resistant, high-strength materials for rockets, missiles, and jet engines, as well as components for control and adjustment equipment. Tantalum is easy to be processed and shaped, so it is used as supporting accessories, heat shield, heater, and radiator in the high-temperature vacuum furnace. Tantalum carbide is used to make cemented carbide.

Boride, silicified, and nitride alloys of tantalum are used as heat release elements and liquid metal sheathing materials in the nuclear industry. Tantalum oxide is used in the manufacture of advanced optical glass and catalysts. In 1981, tantalum was consumed by about 73% of electronic components, 19% of the machinery industry, 6% of transportation, and 2% of the rest.

Stanford Advanced Materials supplies high-quality tantalum products to meet our customers’ R&D and production needs. Please visit http://www.samaterials.com for more information.