Introduction

Capacitor grade tantalum powder is essential for producing high-performance capacitors. These capacitors ensure stability, reliability, and efficiency in many electronic devices. This article examines the various types of capacitor grade tantalum powder and their applications across different industries.

Types of Capacitor Grade Tantalum Powder

Capacitor grade tantalum powder is generally categorized into three series based on the working voltage of the capacitors they are used to produce:

1. Low Voltage Series

This series is designed for capacitors with a working voltage not greater than 25V. The powder in this series is optimized to provide high capacitance and stability at lower voltages.

Low voltage tantalum powder is commonly used in portable electronic devices such as smartphones, tablets, and other consumer electronics that operate at lower voltages. These capacitors ensure reliable performance in compact, energy-efficient gadgets.

2. Medium Voltage Series

This series serves capacitors with a working voltage range of 32V to 40V. It balances capacitance and voltage handling capabilities, making it suitable for a broader range of applications compared to the low voltage series.

Medium voltage tantalum powder is used in telecommunications equipment, automotive electronics, and industrial control systems. These capacitors provide reliable performance in environments where moderate voltage levels are typical.

3. High Voltage Series

This series is designed for capacitors with a working voltage not less than 50V. The powder in this series is engineered to handle higher voltages while maintaining stability and performance.

High voltage tantalum powder is utilized in power supply units, aerospace and defense systems, and high-performance computing. These capacitors ensure durability and reliability in high-stress environments.

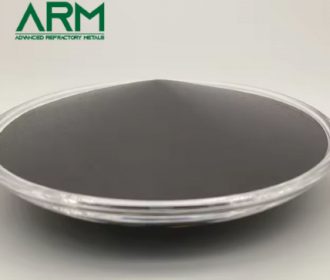

Advanced Refractory Metals (ARM) is a leading supplier and manufacturer of high-quality capacitor grade tantalum powder produced through sodium reduction processes. We offer three types of capacitor grade tantalum powder: 4-20V, 20-40V, and above 60V, all at competitive prices to meet your needs. Send us an inquiry for more quality tantalum products.

Further reading: Tantalum Powder Types & Properties

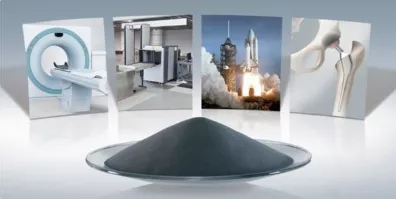

Uses of Capacitor Grade Tantalum Powder

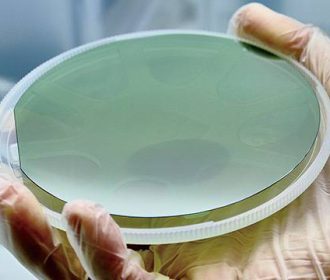

1. Solid Electrolytic Capacitors

– Overview: Solid electrolytic capacitors are one of the most common types of capacitors that use tantalum powder. These capacitors feature a tantalum anode, a solid manganese dioxide electrolyte, and a tantalum cathode.

– Applications: Solid electrolytic capacitors are used in a wide range of applications, including consumer electronics (e.g., smartphones, laptops), automotive electronics, medical devices, and aerospace systems. They are valued for their high capacitance per volume, reliability, and stability over a wide temperature range.

2. Wet Electrolytic Capacitors

– Overview: Wet electrolytic capacitors use a liquid electrolyte instead of a solid one. Tantalum powder is used to create the porous anode in these capacitors.

– Applications: Wet electrolytic capacitors are typically used in high-voltage applications and in environments where high energy density and low leakage current are essential. Common applications include power supply units, industrial equipment, and military electronics.

3. Hybrid Capacitors

– Overview: Hybrid capacitors combine the features of both solid and wet electrolytic capacitors. They use a combination of tantalum powder and other materials to achieve specific performance characteristics.

– Applications: Hybrid capacitors are used in applications that require a balance of high capacitance, low leakage current, and high reliability. They are found in advanced electronic devices, renewable energy systems, and critical infrastructure applications.

4. Medical Devices

– Overview: The reliability and biocompatibility of tantalum make it an ideal material for capacitors used in medical devices.

– Applications: Tantalum capacitors are used in implantable medical devices, such as pacemakers and defibrillators, as well as in diagnostic equipment and portable medical devices. Their stability and longevity are crucial for ensuring the safety and efficacy of medical treatments and monitoring.

5. Telecommunications

– Overview: The telecommunications industry demands capacitors that offer high performance and reliability to ensure uninterrupted service.

– Applications: Tantalum capacitors are used in network infrastructure, including base stations, routers, and switches, as well as in consumer communication devices. Their ability to perform consistently in varying conditions makes them essential for maintaining robust and reliable communication networks.

Advantages of Using Tantalum Powder in Capacitors

- High Capacitance Density

- Tantalum capacitors offer higher capacitance per unit volume compared to other types of capacitors. This allows for the production of smaller, lighter capacitors, which is especially beneficial in portable and miniaturized electronic devices.

- Excellent Temperature Stability

- Tantalum capacitors can operate over a wide temperature range, typically from -55°C to 125°C. This ensures reliable performance in extreme environmental conditions, making them suitable for use in industrial, automotive, and aerospace applications.

- Superior Reliability

- These capacitors exhibit long service life and high reliability. They maintain stable capacitance characteristics under varying temperature and load conditions, which is crucial for energy storage and power supply applications.

- Low Leakage Current

- Tantalum capacitors have low leakage currents, contributing to efficient energy usage in electronic circuits. This makes them ideal for battery-operated devices and applications requiring low power consumption.

Conclusion

Capacitor grade tantalum powder is crucial in the production of high-performance capacitors with excellent electrical characteristics. The different types of tantalum powder, each suited to specific voltage ranges, meet the diverse needs of modern electronic devices. As technology advances, the demand for high-quality tantalum powder will grow, driving further innovation in capacitor design and manufacturing.

Recent Comments